A journey in the cosmetic peptide world: Latest advances and innovations

What are peptides?

Peptides are small, linear chains of amino acids (AA) naturally present in the body. Only very select endogenous peptides are involved in cell metabolism as upstream regulating messengers. They work like a key and a keyhole: specific peptide sequences trigger specific protein production. It means that only a select few peptides, with very specific amino acid sequences, can ‘control’ one or more protein’s production pathway.

Cosmetic peptide challenges

The challenge is to identify sequences of amino acids stimulating the production of molecules that have a primary role in maintaining the skin’s properties. Most of the time, cosmetic peptides are replicas of endogenous skin peptide fragments, which aim to mimic their action in use. Although they may be from synthetic origin, peptides used in cosmetics act in a similar way to those naturally produced by the skin, thanks to their biomimetic action, so could be considered to have a “natural action” on skin.

What are peptides and how do they work?

Watch now

Many peptides have been developed and tested for cosmetic purposes with a wide variety of functional claims beyond anti-ageing, such as:

- Eye care (anti-dark circles and puffiness)

- Lash care (lash growth), lip care (plumping)

- Hair care (counteracting loss and greying)

- Body care (reducing stretch marks)

- Skin microbiome balance

- Reducing pollution damage (blue light)

- Radiance (glass skin)

Peptides involved in the skin’s natural metabolism have the potential to answer many beauty concerns. With appropriate scientific testing to support, many new innovative claims for peptides in beauty products could be made

Ethical and sustainable advances

Due to their synthetic origins, consumers can have a perception that peptides are not sustainable. It’s important to highlight that although synthesised; cosmetic peptides are still made up of short chain of amino acids that are naturally present in the human body, so there is nothing truly “foreign” being added, and that synthetic peptides, most of the time, are made of natural bio-based raw materials which lead close to a 100% natural origin index according to the ISO 16128 standard.

Moreover, the use of solvents that are harmful to people (like CMRs) and the planet (i.e. TFAs) for chemical synthesis of peptides has been drastically reduced over the last 6-7 years. It is also the case for the consumption of solvents overall (for Croda Beauty Actives the reduction reaches 86% for the last 6 years). Progress in the reduction of energy consumption and in waste management is also continuously being made. Several research projects are ongoing to chemically produce peptides more rapidly, with fewer solvents (including water), with higher yields (100% purity). They are based on hybrid systems taking the best of well-known liquid and solid processing technologies.

Peptides of a natural origin are another option to meet the need for both effective active ingredients and the sense of “naturalness” consumers look for. Here, the challenge is to be able to set up protocols that guarantee reproducibility from batch-to-batch with a specific molecule characterisation and purity (and not a blend of molecules that can include allergens). Then, once the purified molecule is obtained, the peptide is as efficient as a synthetic analogue.

Some peptides include a palmitic chain to enable their bioavailability. At Croda Beauty, the palm derivatives used in low amounts to produce these peptides are RSPO certified according to Mass Balance (MB) supply chain model. This is another example of bringing sustainability into peptide manufacturing.

Synthetic biology to produce cosmetic peptides

Advanced development programs will allow, in the near future, the manufacture of peptides without the use of solvents (except water) through new routes, via synthetic biotechnology, in particular from algae. Synthetic biology is a multi-disciplinary field of biotechnology that combines biology, bioinformatics and engineering to build and develop biological systems that do not exist in nature, or to reconstruct existing systems by modifying them. This novel approach allows the development of production alternatives for molecules, like peptides, that have traditionally been manufactured using particular chemistries that may have relied on solvents, catalysts or environmentally unfriendly materials. Synthetic biology also makes it possible to improve some manufacturing processes in terms of time savings or yields, and therefore reducing consumption and costs.

At Croda Beauty, we are pleased to offer the first peptide obtained thanks to synthetic biology: Kerabio™ K31 the first-ever recombinant hair repair protein from an ingredient supplier.

.jpg&mn=beauty&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=55441E1A4912CAA402B044B78739509319C138999FEC74AA) Featured

Featured

KeraBio™ K31

What about peptide encapsulation?

Sustainability efforts are focused on the manufacturing mode of peptides because, once obtained, they are safe and stable molecules that are easy to formulate with. That’s the reason they are so valued. Unlike other hero cosmetic ingredients, like retinol or vitamins, peptides are not prone to degradation and toxicity. Furthermore, benchmarks between peptide efficacy and vitamin C or retinol in fighting signs of ageing are often conducted. For some of them, like the market reference Matrixyl®, the peptide is more efficient. The benefits of encapsulation are known for retinol and vitamin C, reducing their degradation and sensitisation. Peptides do not present similar issues and are more tolerable by different skin types, however these molecules also benefit from controlled release and targeted delivery.

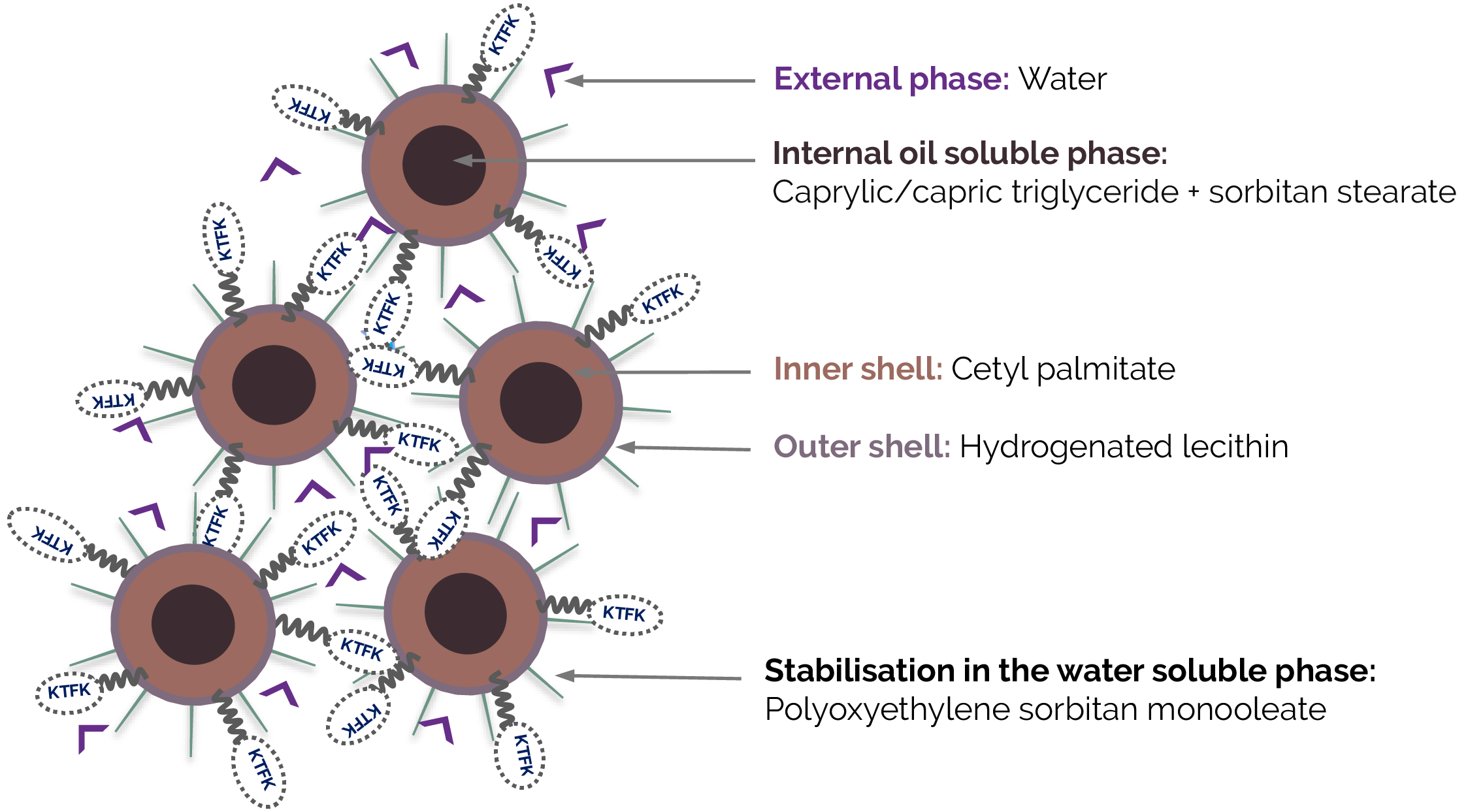

Peptides can promote benefits to different layers of the skin. Delivering them to the correct target is a challenge that can be answered thanks to innovative delivery systems. These delivery systems allow peptides to increase stability, effectiveness and target specific skin layers. For example, peptides that have the epidermis as the site of action can be delivered using novel lipid capsules. Innovative approaches vary in terms of benefit given by the delivery systems. Today, we have available lipid delivery systems that are naturally derived, biodegradable and highly stable.

Fig. 1 Example of peptide encapsulation for optimal delivery to the epidermis

Older delivery systems like liposomes are sensitive to surfactants and are usually unstable in emulsions. The latest generation of lipid systems, consisting of a central oil core surrounded by a mixture of lipids and waxes, circumvents this issue and facilitates the incorporation of peptides in final formulations.

Delivering peptides to the skin’s specific targets can be achieved with deep understanding of the biological effects of the molecule, as well as its physico-chemical characteristics. Unique and specific design of delivery systems, like submicron particles, can allow protection and stabilisation and in the same time control the release, increase the activity and reduce issues.

What’s next?

Peptides and lipopeptides as active molecules in the beauty care industry have made tremendous strides over the past three decades. As a pioneer in the use and development of peptides for cosmetic applications, we are always at the cutting-edge of R&D in this field. We present GAP Peptide Synthesis (GAP-PS) as the next step towards a more sustainable peptide future. GAP-PS is a solution-phase peptide manufacturing technology using a proprietary anchor molecule, with tremendous capability and sustainability advantages. The technology offers critical advantages of up to 30-mer lipopeptide sequences fully synthesised in solution, no CMR or PFAS reagents, and over 80% reduction in carbon waste stream compared to Solid Phase Peptide Synthesis. With Croda’s new state-of-the-art manufacturing site in Pennsylvania (USA), the production of peptides with the advantages of GAP-PS is set to come online next year.

Efficient, increasingly sustainable, safe, biomimetic, easy-to-formulate, peptides belong to the future of cosmetics. Peptides are involved in so many metabolic pathways that the number of applications is tremendous. Combined with the fact that the 20 standard amino acids offer endless possibilities for peptide structures, cosmetic scientists still have a lot of work ahead of them!