Sunscreen formulation strategies to maximise skin protection

What do consumers want from their sunscreen?

The effects of rising temperatures and extreme weather events are shaping consumer behaviours, with many looking to adapt their lifestyles to the daily challenges brought by climate change. This concern extends to both their physical health and general well being. 67% of US consumers believe their skin conditions, including hyperpigmentation and rosacea, are affected by sun exposure [1].

- In a survey of sunscreen users in Europe, 46.5% reported using SPF 50+ in the past year [2], with 39.2% using SPF 30-49.

- This evident shift towards using higher SPF formulations is supported by the total number of sunscreen products with SPF 50+ launched globally increasing from 27% to 39% in the last three years [3].

In addition to protecting the skin from UV radiation, there is also growing interest in maintaining the skins’ resilience against environmental aggressors, including heat and pollutants. Consumers want skin protection solutions that not only promise higher levels of SPF, but that also offer advanced, climate-adaptive protection that will help to mitigate premature skin ageing and promote skin longevity. This is particularly true in the US, where 67% of consumers are interested in products that strengthen the skin to fight against urban pollution [4]. Similarly in China, consumers are looking to prioritise long-lasting protection, skincare benefits, and strong UV protection claims [5].

Consumers understand the importance of sun protection in their skin care regimes but there remain barriers towards both daily wear of sunscreen products and frequent re-application. Sunscreens have a long-standing reputation for being thick or greasy to apply and for leaving a visible white cast on the skin. In a survey of sunscreen users, 60% look for sunscreens that are fast to apply (Europe) [2], 54% express concerns about greasiness or stickiness of sunscreens (Thailand) [6] and 41% are willing to pay more for a sunscreen product that feels good on the skin (US) [7].

Texture innovation is critical to combat the traditional, negative perception associated with the application experience of sunscreens. Products on the market have come a long way in recent years, with a variety of UV filters and formats available that promise to deliver a lightweight, transparent experience that also offers maximum skin protection benefits.

Formulating effective sunscreens to meet consumer demands in terms of performance and aesthetics is complex. The challenge is to balance maximum UV protection claims with a desirable sensorial experience, whilst adhering to global regulatory restrictions.

The next part of the blog will explore various formulation strategies to help cosmetic formulators step up to this challenge, including the choice of UV filter and ingredient selection to optimise the formulation chassis.

How to formulate sunscreen for maximum sun protection benefits with a desirable sensorial experience

UV filter selection

The first critical choice in sunscreen formulation development is the selection of UV filters. This could be either chemical (organic) or mineral (inorganic) UV filters, and the choice between them, or using combinations of UV filter can heavily influence how you formulate with them.

Chemical UV filters can be favoured for their transparency. However, a mix of different chemical UV filters are usually required to meet regulatory requirements for UV protection. Whilst they can present challenges with photostability in formulation, this can be improved by combining with other organic UV filters or with triplet state quenchers.

The most common mineral UV filters, Titanium Dioxide (TiO2) and Zinc Oxide (ZnO), are approved for use globally at a level of 25% and are photostable in formulation. They have long been valued by consumers for their perceived safety, skin compatibility and suitability for sensitive skin. Whilst formulating with mineral filters can require greater technical consideration to achieve desired texture and transparency, advancements in particle science, surface coatings and dispersion technologies mean it is now possible to achieve high levels of UV protection with a smooth, elegant finish and minimal white cast on the skin. At Croda, we offer a range of mineral TiO2 and ZnO UV filters, consisting of powders, oil-based dispersions and water-based dispersions to offer formulation flexibility.

Depending on the desired level of skin protection, formulators could use one broad-spectrum UV filter or a combination of filters which protect from different wavelengths to achieve the desired level of UV protection whilst satisfying the relevant regulatory requirements. Combinations can be chemical-only, mineral-only, or a hybrid system that utilises both chemical and mineral filters. Understanding how to include them in a formulation is important to guarantee stability and high performance.

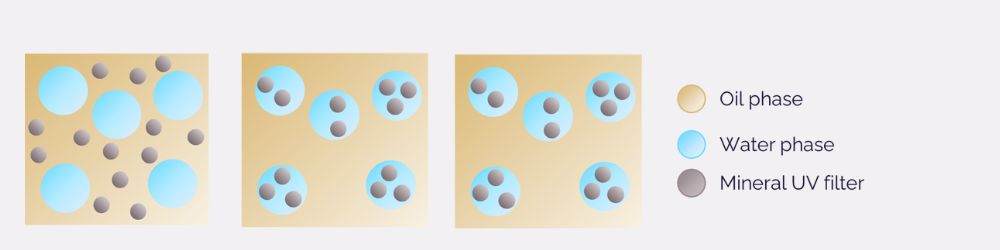

Dispersions of mineral UV filters can be easily incorporated into either the oil or water phase of an emulsion, depending on the emulsion system used, as shown in fig 1 and 1.1.

Water-in-oil (W/O) emulsions

- Oil based dispersions tend to be most suited to the oil phase of W/O emulsions, where the external phase is oil

- The use of water dispersions in the internal phase can be difficult to stabilise

fig 1: Diagram demonstrating the inclusion of a mineral UV filter dispersion in different phases of a W/O emulsion

Oil-in-water (O/W) emulsions

- Water based dispersions tend to be most suited to the water phase of O/W emulsions, where the external phase is water

- Oil based dispersions can be used in the internal oil phase with no stability concerns

fig 1.1: Diagram demonstrating the inclusion of a mineral UV filter dispersion in different phases of a O/W emulsion

For both systems, dispersions can be included in both the oil and the water phase to achieve synergy for maximum SPF performance. This method also allows for a higher loading of solids and can help with stability.

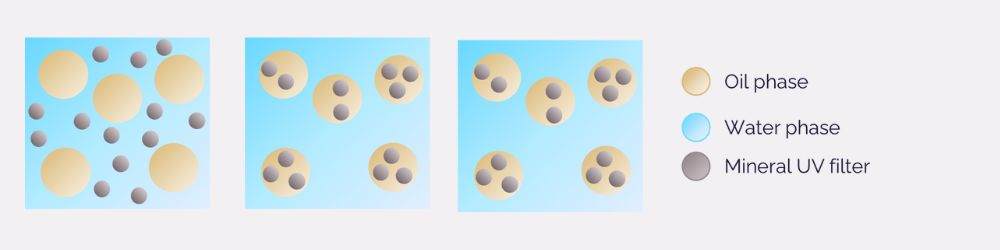

Combining chemical and mineral UV filters in different phases of a formulation is a great option to achieve high SPF formulations, a strategy known as the biphasal distribution of actives. Mineral UV filters can be used as a photostable base that can be built upon with chemical filters, with multiple processes of scattering and absorbing UV light resulting in greater SPF performance compared to that of the individual ingredients used in isolation.

fig 2: scattering and absorption of UV light in hybrid sunscreens utilising the biphasal distribution of actives can promote a synergistic SPF boosting effect

Such hybrid systems can allow the creation of sunscreen formulations that are more lightweight than traditional mineral-only systems, with greater photostability and a less greasy sensory than organic-only systems. A higher loading of solids can also be achieved without reaching restricted inclusion limits for individual UV filters.

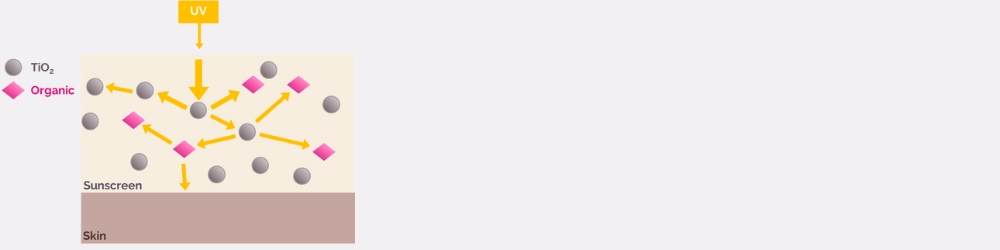

The synergistic SPF boosting effect offered by the biphasal distribution of chemical and mineral UV filters has been proven in a study using our water-based TiO2 dispersion, Solaveil™ CT-60W. Three oil-in-water (O/W) formulations were created, with the only difference being the UV filter used.

1. Organic only

Octocrylene (OCR) (6%) + Bis-Ethylhexyloxyphenol Methoxyphenyl Triazine (BEMT) (4%)

2. Inorganic only

Solaveil CT-60W (2.8% solids – 7.7% w/w)

3. Organic + inorganic

OCR (6%) + BEMT (4%) + Solaveil CT-60W (7.7%)

The graph in fig 3 shows the results of the individual UV filters are approximately SPF 10 and 5, which would give a total maximum value of 15, whereas the combination of chemical and mineral UV filters gives an in-vivo SPF of approximately 40. This test demonstrates the benefit and resulting synergy of utilising chemical UV filters in the internal phase and a water-based TiO2 UV filter in the external phase.

fig 3: in-vivo SPF values of O/W formulations containing different UV filter systems

Formulating with hybrid systems can be tricky. Some chemical UV filters are not permitted for use in combination with mineral UV filters in some countries, and others, such as Avobenzone, can form coloured complexes in combination with TiO2. This does not impact the performance of a formulation but can lead to yellowing over time. The biphasal distribution of actives helps to prevent this from happening, where chemical and mineral UV filters are added to separate phases of the formulation to minimise interaction.

Discover our Water-based Titanium Dioxide Dispersions

SPF boosters

SPF boosters are a well know way of maximising the performance of UV filters in sunscreen formulations. They can help to minimise the cost of a formulation by reducing the levels of UV filter required. This can also help to ensure global regulations related to usage levels are adhered to, whilst still maintaining the desired level of UV protection. By enabling the use of less UV filter, SPF boosters can also help to improve the skin feel and transparency of the formulation, particularly for mineral UV filters.

SPF boosters can employ different modes of action to improve the efficacy of a sunscreen formulation. They can typically:

Improve film formation – it is essential that the sunscreen is evenly distributed over the skin surface for maximum protection, ensuring that a coherent protective film is formed on the skin after application and dry-down

Our solution: SolPerform™ 100, OleoCraft LP-20

Increase UV scattering – enhanced scattering and reflectance of UV light ensures less interaction with the skin

Our solution: ChromaPur™ CV2 and ChromaPur™ CV7

Modify formulation rheology – product rheology is critical to ensure that the sunscreen can spread easily over the skin during application, with a rapid recovery of structure after spreading to maintain an even film

Our solution: Syncrowax™ SB1, Seatons Rice Bran Wax

Discover our range of SPF boosters

Impact of chassis ingredients

Emulsifiers

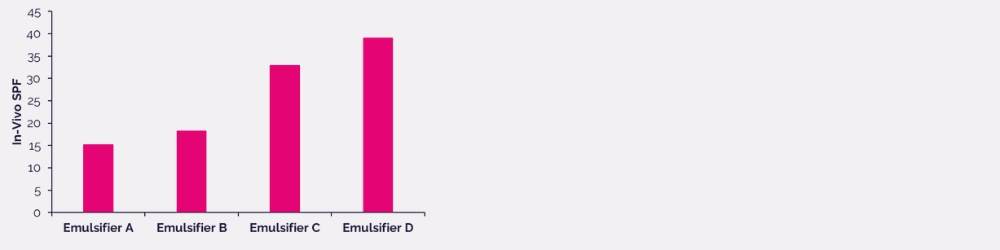

SPF is not only dependent on UV filters or SPF boosters. The theoretical approach to achieving a higher SPF is to increase the amount of UV filter, however other ingredients and the structure of the formulation are a critical consideration to ensure maximum performance.

Our research has explored the impact of different chassis ingredients on the performance of sunscreens. Over 100 formulations were developed and tested as part of this research, each with varying emulsifiers and waxes, but using the same UV filter at the same inclusion level. Each formulation was evaluated for SPF (in-vitro and in-vivo), whitening, stability, rheology and microscopy to understand how differences in the chassis ingredients impacted the structure and performance of the resultant formulation.

The graph below shows the in-vivo SPF level of four different oil-in-water (O/W) formulations, each using the same UV filter (a water-based TiO2 dispersion) at 15% w/w, with the only difference being the emulsifier used. For the same inclusion level of the UV filter, in-vivo SPF ranged from 15 to 40, demonstrating that emulsifier choice can have a significant impact on the achievable UV protection claims.

fig 4: in-vivo SPF values of O/W formulations containing different emulsifiers

The thickness and the spreadability of a formulation can also significantly impact the amount of UV protection a formulation can provide. If the layer of formulation is not homogenous upon application to the skin, the SPF will be lower. Film-forming ingredients can help optimise the distribution of the UV filter, but it is the formulation chassis which will determine the application properties. The rheology, or flow, of the formulation must therefore be optimised to maximise SPF.

As part of our research, we observed a correlation between in-vivo SPF and the rheology of a formulation. The graphs shown in fig 5 show the in-vivo SPF and viscosity measurements for various water-in-oil (W/O) formulations, where three W/O emulsifiers were evaluated in combination with different waxes. We can see that the SPF levels range from 15 to 42, demonstrating how emulsifier and wax choice can impact the structure of a sunscreen formulation, therefore impacting the performance.

fig 5: in-vivo SPF values and viscosity measurements of W/O formulations containing different emulsifiers and waxes

When we compared the SPF performance with formulation rheology, we identified that there was a 99.9% probability of correlation between in-vivo SPF and the rheology at spreading, which suggests that the viscosity of a formulation at spreading is more important than the viscosity at rest. This can allow formulators to develop fluid formulations with an increase of viscosity at spreading to achieve higher SPF levels.

Discover our range of emulsifiers and waxes

Emollients

The last thing consumers want after applying a sunscreen is a white cast to be left on their skin. We have found that emollients can help enhance the transparency of mineral sunscreen formulations, making the choice of emollient critical.

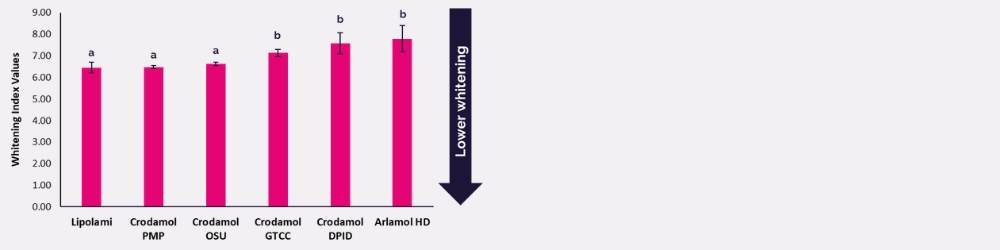

We studied six different emollients in W/O formulations containing Solaveil Harmony powder at 15% w/w. This is an intermediate particle size titanium dioxide-based UV filter which provides both UVA and UVB protection. Various parameters for each formulation were assessed, including whitening and in-vitro SPF.

fig 6: whitening index values of W/O formulations containing different emollients, where the set of equal letters represents statistical equality ( p>0.05)

fig 7: whitening visual assessment of W/O formulations containing different emollients

All of the parameters were evaluated showed that formulations containing Lipolami™ ER, Crodamol™ OSU and Crodamol™ PMP delivered the lowest whitening on the skin without impacting in-vitro SPF performance, demonstrated by both whitening index measurements and visual assessment, as shown in fig 6 and 7. This suggests that the choice of emollient can also impact sunscreen formulation aesthetics, particularly relating to transparency.

Discover our range of emollients to enhance transparency

As consumer demand for sunscreen products becomes more complex and blurs the lines with skin care, the ability to create inspiring, high efficacy skin protection products is critical. By adopting formulation strategies that balance performance with desirable aesthetics, cosmetic formulators can create next-generation sunscreens that offer safe and effective UV protection.

References

[1]– Mintel Report: Skin Conditions – US – 2024

[2] – Mintel Databook: Suncare - Europe - 2023

[3] – Mintel GNPD

[4] – Mintel Report: The Personal Care Consumer – US, 2023

[5] – Mintel Report: Trending in China: suncare

[6] – Mintel Report: Patent insights: advancements in sunscreen

[7] – Mintel Report: Suncare and Skin Protection – US – 2025

.jpg&mn=beauty&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=733B36D134DCAC67202EB7308F77DF6019C138999FEC74AA)

(2).jpg&mn=beauty&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=6D6E1C81815F36DBD89A875F7C5E6E7519C138999FEC74AA)

.jpg&mn=beauty&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=64A5886C3E921CC33283ACAD6772200419C138999FEC74AA)

.jpg&mn=beauty&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=00FBB915A4E185FA2705A0DDE5D7493019C138999FEC74AA)